LEAKY BOOT

SYNDROME

Before anything else check thoroughly for rust holes in both wheel arches. Peel back the boot carpet and shine a bright light around the wheel arch while an assistant looks for light penetration inside the boot. This may help in spotting small holes. Even a tiny hole can allow significant amounts of water to enter the boot. Pay particular attention to the towing eyes that are welded to the wheel arch. Water can penetrate up between the towing eye and the wheel arch and then into the boot area.

The

following chart gives details of points of entry where water may

get into your boot together with some information to assist in

diagnosis and rectification. You can establish most of this with

2 people and water testing just deciding who is the unlucky one

to get wet. Kaz always loses on this one.

POINT OF ENTRY |

PROBLEM |

RECTIFICATION |

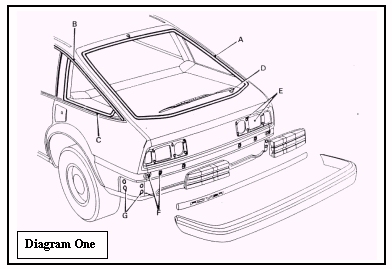

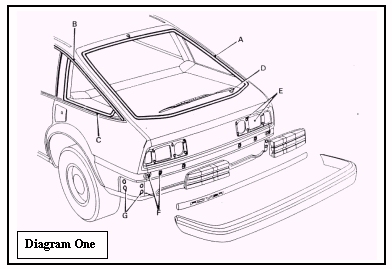

Tailgate Glass seal (A in diagram 1) |

Water passing between seal

& glass or between seal & tailgate |

Reseal using a window

sealer paying particular attention to corners. Check also

that wiper motor is not fouling parcel shelf as this

tends to push screen outwards and break seal on lower

edge. |

Drip Moulding flange (B in diagram 1) |

Crack or pinhole in drip

moulding. Sealant Can allow water to enter and run down

between e posts & drip moulding & emerge below ¼

light seal. Note water entry at this point can be

mistaken for a ¼ light leak |

Reseal flange with sealant

note it may not be necessary to remove chrome strip to

carry out this operation if a suitable tool such as a

small screwdriver is used for the application of the

sealer. |

Quarter light (C in diagram

1) |

Leaking between seal and

body or seal and glass |

Reseal insuring that

quarter light is set correctly in aperture |

Wiper motor (D in diagram 1) |

Water entry passed rubber

grommet in tail gate glass |

Gain entry to grommet and

apply sealant to area and reassemble |

Tail lamps (E in diagram 1) |

Water passing between lamp

and body and entering boot |

Apply sealant around lamp

gasket over lapping on to body and lamp |

Rear motive (F in diagram 1) |

Water entry through holes

for plinth securing bolts |

Ensure grommets are fitted

between plinth and body and apply sealant between

grommets and body |

Rear bumper mountings (G in diagram 1) |

A loose mounting or missing

rubber gasket will allow water to travel along mounting

bolts in to the boot |

Insure rubber gaskets are

fitted apply sealant around bolt heads and tighten bolts |

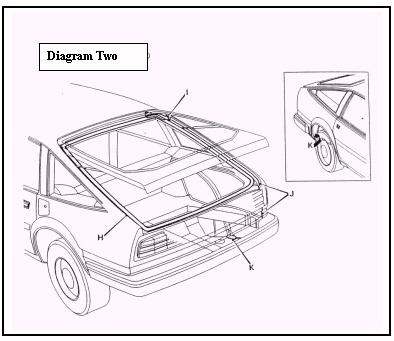

Tailgate seal (H in diagram

2) |

Seal not fitting correctly

on top corners of flange a build up in this area can

cause water to enter seal carrier and travel down the

seal dripping out at lower point |

Dress flanges to ensure

seal fits properly make sure flanges are fully home

ensure that seal is fitted with uppermost lip pointing

outwards |

Wiring sheath between

tailgate and E post left hand and right hand (I in

diagram 2) |

Water passing between

grommet and tailgate aperture and running down inside E

post into boot |

Check for cracks splits in

sheath and ensure grommet is fitted correctly in E post.

If necessary apply sealant between grommet and E post |

Tail gate aperture seams and back panel wing vertical seams (J in diagram 2) |

Water entry through cracks

or pinholes in sealer |

Reseal aperture seams and

back panel wing seams and repaint |

Rear wheel arch (K in

diagram 2) |

Water entry through double

panel joint on rear lower flange |

Seal joints inside boot

adjacent to sunroof drain tube |

Sunroof motor (if fitted) |

Water entry passed motor

fixings in boot floor |

Remove motor and apply

sealant around fixing bolt threads and refit motor |

Tailgate

support struts

|

Water entry passed mounting

struts on tailgate aperture |

Remove nut apply sealant to

both sides of mounting and washer and tighten nuts |

Verify by water testing again.

roversd1mania 1997 - PRESENT